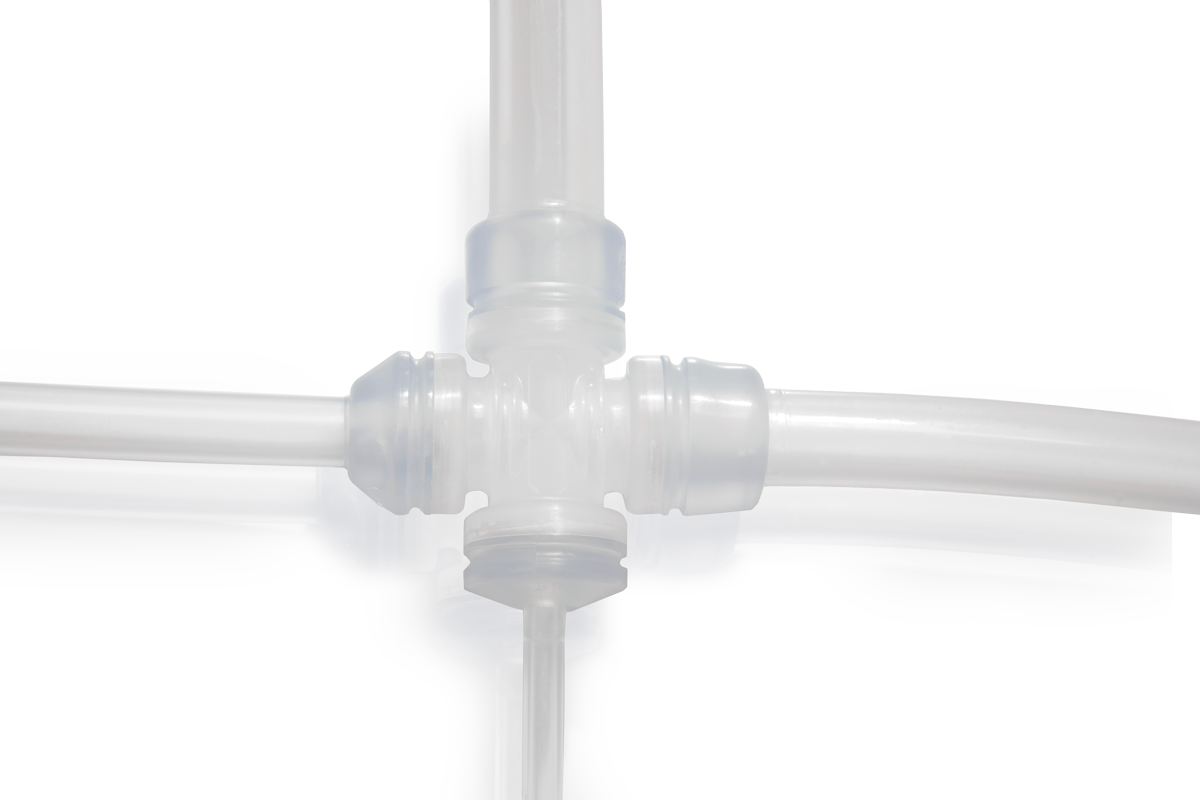

BioLink® Modular Overmolding Technology

Let's talk.

Send a message to our

industry experts.

BioLink®

Let's talk.

Send a message to our

industry experts.

BioLink®

Delivering enhanced connectivity with increased security for your process

BioLink® modular overmolding combines the best attributes of conventional overmolding with the flexibility and speed of processing often associated with traditional mechanical connections. It also offers enhanced process robustness over conventional overmolding while facilitating additional secure connectivity to processing steps, such as filters.

BioLink® modular overmolding consists of two basic components: (1) lengths of M-Flex® TPE tubing with overmolded unitized end-fittings and (2) polypropylene modules and filter adaptors injection molded out of the exact same resin as the bulk of our filter product portfolio. All connections are created via automated welding processes that result in permanent thermal bonds between fluid path components with a smooth inner bore.

BioLink® modular overmolding technology can be applied to the tubing sizes and connectivity indicated below. (Any size tubing can be adapted to any module or filter.)

| Tubing Sizes | Connectivity |

|---|---|

| 1/8″ ID x 1/4″ OD | Union Module |

| 1/4″ ID x 7/16″ OD | Single Bifurcation Module (T-fitting) |

| 3/8″ ID x 5/8″ OD | Dual Bifurcation Module (X-fitting) |

| 1/2″ ID x 3/4″ OD | Filters |

- Reduced number of fluid contact materials

- Increased process robustness

- Enhanced connectivity to filters and SGTs (single-use gauge tees)