TepoFlex® PE Biocontainers for Freeze & Thaw

Applications

When it comes to freeze-thaw processes, not all single-use containers are created equal. For flexible biocontainer-based systems, the TepoFlex® biocontainer stands apart with film strength and weld integrity that has been proven to perform under the mechanical and thermal stresses of freeze and thaw. With over 15 years of demonstrated robustness across diverse applications—including the demanding freeze and thaw workflow—TepoFlex® delivers the security you need to reduce risk in this critical processing environment. Meissner supports our clients’ success in this application by offering comprehensive onboarding consultation, inclusive of an extensive data and documentation package tailored to freeze and thaw applications.

Proven Strength. Precisely Controlled Weld Integrity.

What sets the TepoFlex® freeze thaw biocontainer apart from other existing biocontainers deployed in freeze and thaw applications is not only the durability of the film, but also the precision and strength of the welds. Each weld is created under tightly controlled manufacturing conditions, with energy input carefully measured and monitored to ensure consistent weld strength across every biocontainer. This level of process control reduces the risk of weak points that can lead to cracking or leaking during freeze-thaw cycles. Combined with a film that resists brittleness at low temperatures, the result is a biocontainer you can trust to protect your product under the most demanding conditions.

Key Features & Benefits

- Workflow Integration – Compatible with existing freeze-thaw platforms, clamshells for freezing, and freezer types.

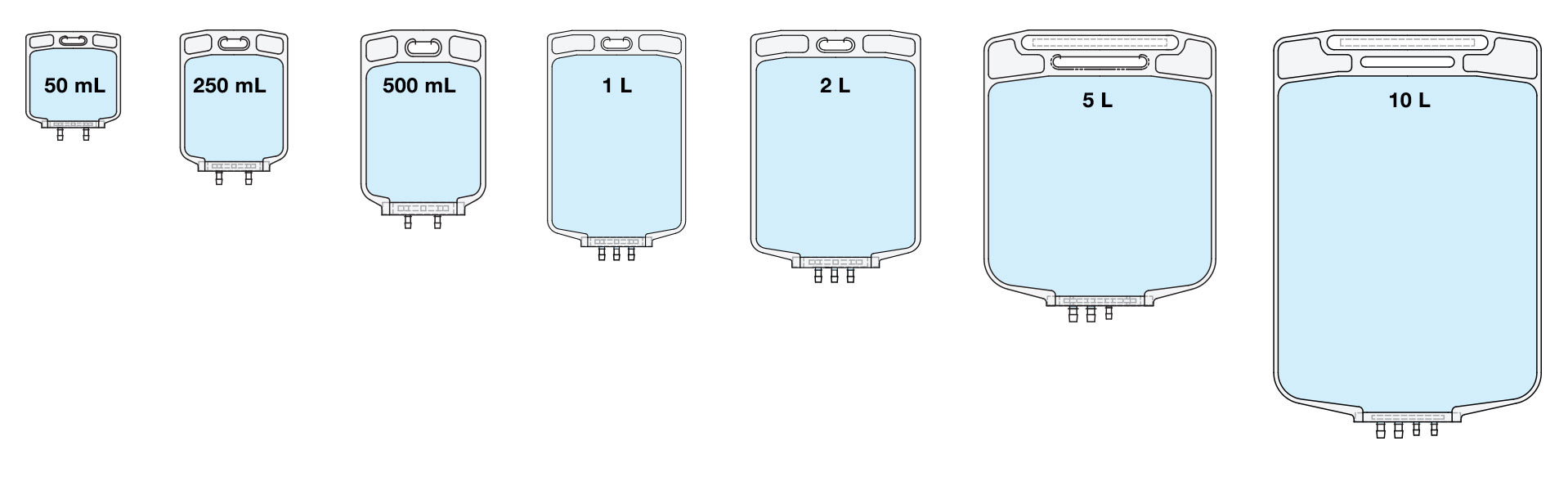

- Scalable Volume – From development to commercial scale, TepoFlex® biocontainers are available from 50 mL to 10 L.

- Secure – Withstands the stresses of freezing and thawing without compromising product integrity.

- Quality-Driven Compliance – Manufactured in ISO-certified cleanrooms with qualified componentry to ensure biocompatibility and support regulatory compliance. Learn More.

- Application-Driven Support – Our Applications Engineering team offers consultation in the design and optimization of your single-use system, customized to your application and quality requirements.

If you require the utmost security in your freeze and thaw application, the CryoVault® platform offers a complete end-to-end freeze and thaw solution.

Let's talk.

Send a message to our

industry experts.

TepoFlex® PE Biocontainers for Freeze & Thaw

TepoFlex® Brochures

TepoFlex® Standards Guide

TepoFlex® FAQ

Biocontainer Sizes / Volumes

Freeze & Thaw Platform FAQs

TepoFlex® 2D biocontainers are suitable for freezing down to -80°C. The packaging system that supports the filled assembly and operating procedures during freezing, potential transport, and thawing, should also be qualified for the application by the user.

Absolutely, we offer a variety of port configurations, biocontainer sizes, and connectors tailored for your application. Our team of Application Engineers can support the design of custom single-use systems to meet your unique process requirements integrating into existing infrastructure without requiring major equipment or process changes.

We offer a range of standard sizes/volumes including 50 mL, 250 mL, 500 mL, 1 L, 2 L, 5 L, and 10 L. Custom sizes are also available upon request to suit specific process requirements.

TepoFlex® biocontainers are optimized for critical biopharmaceutical manufacturing applications compatible with freeze-thaw processes, including but not limited to those associated with monoclonal antibodies, recombinant proteins, cell and gene therapies, and bulk drug substances.

Yes, the TepoFlex® biocontainer is designed to perform reliably in all freezing methods. Whether you have a blast freezer, static freezer, or plate-based system, our Applications Engineering team will design your single-use assemblies for robustness through the entirety of your freeze-thaw cycle.

Absolutely. TepoFlex® biocontainers maintain structural integrity at deep-frozen temperatures. It is critical to ensure that the packaging system and transportation parameters are also qualified for the application. Our team of Applications Engineers is available to support you through your qualification process, providing guidance where applicable, to ensure your system meets the necessary standards.