Ultradyne® PTFE Membrane Filter (Hydrophobic)

Let’s talk.

Send a message to our

industry experts.

Ultradyne®

Let’s talk.

Send a message to our

industry experts.

Ultradyne®

PTFE membrane filters providing the utmost assurance of chemical resistance, durability, and critical filtration performance in aggressive fluids.

Ultradyne® absolute-rated polytetrafluoroethylene (PTFE) membrane filters offer the highest level of assurance of chemical compatibility and filtration performance in aggressive chemicals, prolonged hot air service, and other severe process conditions. Ultradyne® filters’ PTFE membrane delivers superior flow rates and long service life. The highly porous membrane is inherently hydrophobic and offers maximum chemical compatibility with minimal extractables in a wide range of fluids and applications. Support components are all-polypropylene.

Design Features

- Absolute liquid ratings from 0.1 µm to 1.0 µm

- Meets ASTM bacterial validation standards

- Superior flow rates at low pressure drops

- Ultraclean – no additives, surfactants, or post-treatments

- Inherently hydrophobic PTFE membrane

- Wide chemical compatibility

- Extended service life in sterilizing hot compressed air

- Minimal extractables levels

- 100% integrity tested

- Cleanroom manufactured

Ultradyne® PTFE membrane meets the critical demand for contamination control in the chemical, microelectronics, aerospace, biologicals, pharmaceuticals, food and beverage, and other industries. The Ultradyne® cartridge is designed for the removal of particulates, colloids, and microorganisms from aggressive solvents, highly corrosive chemicals, and gases. It is ideal for bulk and point-of-use filtration. Typical chemicals include:

- Highly concentrated acids

- Bases

- Alcohols

- Chlorinated and fluorinated solvents

- Esters

- Ketones

- Photoresists

- Etchants

- Photolithographic solutions

For aqueous solutions, the Ultradyne® PTFE membrane filter must be pre-wet by immersion in a suitable low surface tension fluid. The inherently hydrophobic Ultradyne® PTFE membrane filter is ideal for gas filtration applications that include:

- Compressed air

- Fermentation air

- Pressurized gases

- Tank venting

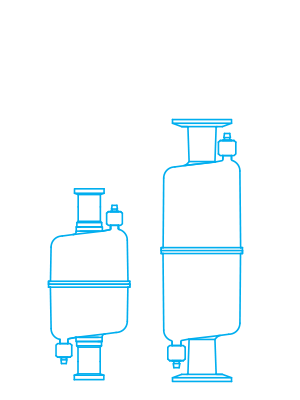

Filter Configurations Available for Ultradyne®

Typical water flow rates per 10″ cartridge

Typical air flow rates per 10″ cartridge